Vickers Hardness Testers Comparison

Get A Quote

Overall rating

5 out of 5

3 out of 5

3.5 out of 5

4 out of 5

4.5 out of 5

Image

Industry Standards

ISO 6507, ASTM E-384

ASTM E-384/92

Not Listed

ASTM E384 & E92, EN-ISO 6507 and JIS

ASTM E384 & E92, EN-ISO 6507 and JIS

All testers appear to be in accordance with ASTM E384 except for Leco which does not advertise this information. Phase II is in accordance with a very outdated version of the ASTM standard dating back to 1992.

Test Forces

- 10g (0.098N)

- 25g (0.245N)

- 50g (0.49N)

- 100g (0.98N)

- 200g (1.96N)

- 300g (2.94N)

- 500g (4.9N)

- 1000g (9.8N)

- 0.098N(10g)

- 0.246N(25g)

- 0.49N(50g)

- 0.98N(100g)

- 1.96N(200g)

- 4.90N(500g)

- 9.80N(1000g)

- 10g (0.098N)

- 25g (0.245N)

- 50g (0.49N)

- 100g (0.98N)

- 200g (1.96N)

- 300g (2.94N)

- 500g (4.9N)

- 1000g (9.8N)

- 10gf

- 25gf

- 50gf

- 100gf

- 200gf

- 300gf

- 500gf

- 1000gf

- 2000gf (optional)

- 10gf

- 25gf

- 50gf

- 100gf

- 200gf

- 300gf

- 500gf

- 1000gf

- 2000gf (optional)

The load capabilities remain the same for all models of the micro hardness testers. All models have the 8 testing forces along with a 2000gf optional load.

Vickers Scales

- HV0.01

- HV0.025

- HV0.05

- HV0.1

- HV0.2

- HV0.3

- HV0.5

- HV1

- HV2 (Optional)

Not Listed

Not Listed

- HV.1

- HV.25

- HV.5

- HV.1

- HV.2

- HV.3

- HV.5

- HV1(HV2)

Not Listed

All Vickers Scales are the same for each micro hardness tester. This can be based on the testing forces available in the previous row.

Converting Scales

HRA, HRC, HR15N, HR30N, HR45N, HB

Not Listed

Not Listed

Not Listed

Not Listed

While all units should have the capabilities of converting your hardness values to other hardness scales, the NextGen model advertises the available scales for converting.

Digital Encoder Resolution

0.01 μm

Not Listed

0.1 μm

Not Listed

0.1 μm

The digital encoder resolution appears to be the same across the 5 Vickers hardness testers. Some manufactures do not list this specification.

Hardness Values

1HV – 4000HV

1HV~2967HV

Not Listed

Not Listed

Not Listed

The achievable value ranges are not commonly advertised, however, NextGen has the highest available range from 1HV – 4000HV.

Eyepiece

10x Magnification Eyepiece

10x

Eyepiece10x

Eyepiece15x

10x

Qualitest appears to provide their customers with higher levels of magnification by providing a 15x eyepiece. Others find that the 10x magnification paired with their objectives is sufficient for observation and measurement.

Objectives

10x (Observation) and 40x (Measurement)

10x, 40x

10X and 50X are included

Objectives 10x,40x

10x, 50x (SWD)

All manufactures provide a 10x objective for observing your specimen and for positioning the indentation. The measurement objective varies across the board from 40x to 50x.

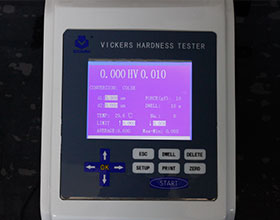

Display Panel

The Qualitest, Buehler and NextGen Vickers hardness testers tend to have a slightly larger screen which can make the operations slightly easier for the operator in your laboratory. The Leco and Phase II hardness testers provide a very small digital or LCD panel for setting the parameters of the test taking away from the ease of use.

Magnification

100x (Observation) and 400x; (Measurement)

100×400×

For measurement: 500X (Objective 50X; Eyepiece 10X) For observation: 100X (Objective 10X; Eyepiece 10X

150x; (observation), 600x; (measurement)

100x, 500x total

Total magnification differs between 100-150x for the observation purposes while the indentation reading ranges from 400x-600x. These ranges of magnification are all acceptable for Vickers hardness testing.

Loading Method

Automatically – Load, dwell and unload the testing force

Automatic (loading / holding-up of the load / unloading)

Automatic loading and unloading

Fully automatic loadcontrol

Automatic (loading / dwell / unloading)

These testers all provide automatic load and unloading control.

Dwell Time

1 - 99 seconds

(5 - 60)S

5 to 99 seconds

5 to 60 sec (5 sec increments)

5 - 99 seconds

Phase II and Qualitest have the lowest selectable dwell time ranges. NextGen provides their customers with the ability to select as low as 1 second dwell time. The others remain consistent with 5-99 seconds.

Turret

Automatic Motorized Turret – Objective Lenses and Indenter

Auto-Turret

Automatic

Motorizedturret

Motorized, 3 position turret (1 indenter, 2 objectives)

All testers feature motorized turrets with 3 positions (1 for the indenter while 2 positions are dedicated for the objectives).

Specimen Test Height

85mm

70mm

(3.6 in.) 91 mm

85mm(2.55")

without anvil 130 mm (4.7 in) / with manual XY-stage 95 mm (3.7 in)

Buehler allows for the highest specimen test height reaching up to 95mm or 3.7”.

Throat Depth

120mm

95mm

Max. Depth of Specimen (4.3 in.) 110 mm

90mm (3.35") (fromcentre)

5.1in [130mm]

Buehler has the highest throat depth reaching 13cm or 5.1”.

Light Source

LED Cold light source (no heat generated from light source – service life of light source can reach 100,000 hours)

Cold Light Source

6V18W Automatic brightness reduction during loading sequence

12V-30W

LED

Leco and Qualitest are outdated machines with standard light bulbs. Buehler, NextGen and Phase II are equipped with LED cold lighting sources for heatless operations.

Stage

Dimensions of the X-Y Testing table are 10cm×10cm

Maximum Travel Range 2.5cm × 2.5cm

Moving Resolution Ratio 0.1mm

Maximum Travel Range 2.5cm × 2.5cm

Moving Resolution Ratio 0.1mm

100×100mm, Movement 25×25mm, Resolution 0.25um

Dimensions: 3.9 in. × 3.9 in. (100 × 100 mm) • Max. Movement: 1.0 in. × 1.0 in. (25 × 25 mm)

100 ×100mm, Travel Range 25 × 25mm, Resolution 0.01mm (micrometer)

Manual 100 × 100mm stage, 25 × 25mm travel

All basic manual anvils have the same specifications for size and travel.

Warranty

5 years

5 Years

Not Listed

Not Listed

Not Listed

While we can imagine that Qualitest, Leco and Buehler would also provide a warranty on their equipment, NextGen and Phase II offer and advertise a 5 year warranty on their micro hardness testing systems.

Power Source

110V / 60Hz / 1Ph

110/220V, 60/50Hz / Cold Light Source

100 to 220V switchable 50/60 Hz

110-220V, 50Hz

100 - 240VAC, 60/50Hz

All systems are capable of running on standard North American outlet requirements, however, Qualitest advertises only 50Hz frequency.

Dimensions

49cm × 18.5cm × 51.5cm (L × W × H)

425 × 245 × 490mm

19.7 in. H × 17.1 in. D × 7.3 in. W (499 mm × 435 mm × 186 mm)

470 × 210 × 420mm

20.5in [521mm] × 9in [229mm] × 20.5in [521mm]

Dimensions of the testers are all fairly similar.

Weight

45kg

41.5kg Net Weight: 35kg

Approximately 79.4 lb. (36 kg)—including standard accessories

36kg

88 lbs [40kg]

Weight of the testers are all fairly similar.

What's in the box?

- Vickers Hardness Tester

- 10X Digital Micrometer eyepiece

- 10X and 40X objective lenses

- Vickers Diamond indenter

- Motorized Turret

- 1x Certified Vickers Test Block (NIST traceable)

- X-Y Testing Stage

- 3-Stage Fixtures

- Power Cable

- Dust Proof Cover

- Instruction Manual

- Hardness Conversion Table

- Certificate of Quality

- Warranty Card

- Accessory Case

- CD with Image Analysis Software

- Digital CCD Camera

- USB Drive with Software and USB Data cable

- Base Machine w/ Auto-Turret

- X-Y Stage w/ Micrometer

- Mini Thin Part Holding Fixture

- Mini Drill Chuck Fixture

- Mini Vise fixture

- Video Cam w/Adapter

- Measurement Software

- USB Cable

Not Listed

- Main unit with CCD Camera and monitor

- Motorized turret

- Diamond indentor

- Vickers

- Objectives 10x, 40x

- Eyepiece15x

- XY-stage with micrometers

- Adjustable feet (3pcs)

- Clamping devices (3pcs)

- Extension tube for CCD-camera

- Digital eye piece incl. protection cover Spirit level

- Micro-Vickers test plates(2pcs)

- Spare light bulb12V-30W

- Spare fuses (2pcs)

- Installation and usermanual

- Instrument scertificate

- 1 Vickers indenter

- 10x & 50x objective

- Auto-turret

- Touch LCD

- Accessories in suitcase including eyepiece

- Standardized test-block and analog stage. This unit does not support automation accessories

Optional Items

15x Eyepiece, 2000gf Load, Dual Vickers/Knoop Indenter

Not Listed

Objectives ranging from 2.5X to 100X are available as options

Dual indentor (Vickers/Knoop) turretoptional, 2kg loadoptional

2kg option.

2kgf is an advertised optional load for NextGen, Qualitest and Buehler. Leco provides the option to change your objectives from a range from 2.5x – 100x. Dual indenters are also advertised by NextGen and Qualitest for operators demanding a high volume of Knoop testing.

Overall

NextGen advertises the 5 year warranty along with a NIST traceable block included with the standard package. They include a large screen on the tester for ease of use and have the highest dwell time available. NextGen provides a recommended solution for a micro hardness tester.

Phase II advertises the 5 year warranty. The style of the hardness tester is more outdated with having a small screen for the operator to set testing parameters. Phase II also has a machine that follows a very outdated (1992) version of the ASTM E384 standard. Overall, Phase II's system needs to be upgraded to be in accordance with the latest industry standards. An upgrade to the screen is also necessary to stay competitive with the other brands available.

The physical appeal of the Leco system is far outdated and does not provide the operator with a clear LCD display for setting test parameters. Optional items may benefit some users by allowing for the switching of objectives from as low as 2.5x and as high as 100x. It is equipped with an older fashion light bulb which may cause heat from continuous use. It is uncertain if NIST traceable accessories are paired with the Leco hardness tester.

Qualitest offers a solution with a large screen and the highest levels of magnification for both indentation placement and measurement. The lighting source is an outdated standard bulb which can cause higher levels of heat for continuous use. It is uncertain if NIST traceable accessories are paired with the Qualitest hardness tester.

The Buehler system rates highest in visual appeal. It is equipped with a clear 4.7' touch screen interface allowing the operators to make their necessary selection before the test. Paired with a 50x eyepiece, the Buehler system allows for one of the highest magnifications in this comparison. Buehler's Tukon 1102 also has the highest available specimen height and throat depth. Buehler provides another recommended option for a micro hardness tester.

Overall rating

5 out of 5

3 out of 5

3.5 out of 5

4 out of 5

4.5 out of 5

Get A Quote